Magnolia

Magnolia (Magnolia grandiflora) is used principally in the manufacture of furniture, boxes, pallets, sash, doors, veneer, and millwork. The wood of magnolia is moderately heavy (32lbs./cu.ft.), moderately low in shrinkage, moderately low in bending and compressive strength, moderately hard and stiff, and moderately high in shock resistance. It has been estimated that there are about 20 species of Magnolia in the world, principally in the United States and Asia, with about 7 species native to the United States. As a commercial wood Magnolia includes Cucumber, Evergreen and Sweet Magnolias although most commercial Magnolia lumber is made from Evergreen lumber. The principal stand of Magnolia timber is in the South, and is most abundant in eastern Tennessee, the Carolinas and the Gulf coast region. From an estimated stand of over one billion feet of timber, about 40 million board feet of lumber is produced annually on a commercial basis.

Cucumber Magnolia is sometimes sold as "Cucumber" lumber and considerable Cucumber and some Evergreen Magnolia is sold as yellow Poplar in the lower grades although this practice is not quite so prevalent since it was discovered that Magnolia was an excellent wood for certain special uses. Magnolia is very closely related to Yellow Poplar and has many of its characteristics although it is harder and heavier. As a matter of fact, microscopic examination is often required for the positive separation of Yellow Poplar and Magnolia.

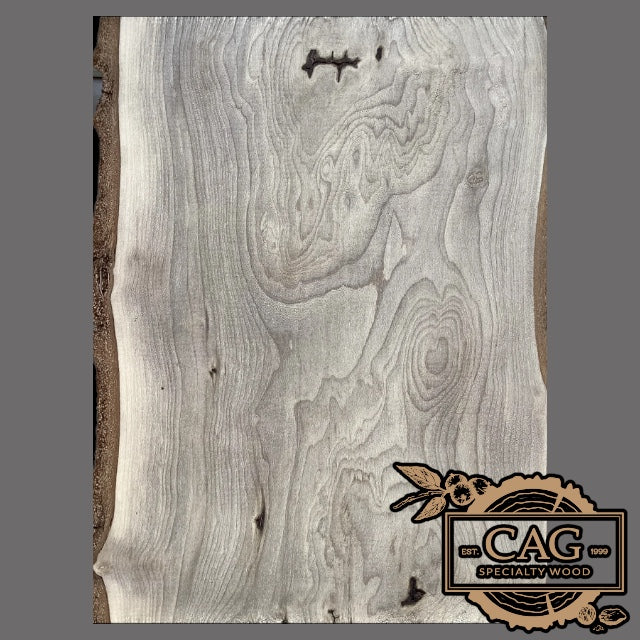

The sapwood of Magnolia ranges from a creamy white to a light yellowish brown to present an attractive blonde color. The heartwood is light to dark brown or purplish black, sometimes tinged with yellow or green. While the lighter sapwood lumber is generally preferred for most purposes, some mills produce a selected black heart lumber for paneling which lends itself to striking panel effects. The color in the lower grades is usually a greenish yellow with an occasional burl or dark streak. While Magnolia is definitely not one of the leading veneer woods, veneer is produced from the white wood of Magnolia logs and is sometimes marketed under the trade name "Ailon." Magnolia veneer generally has mild grain markings and is usually produced by quarter slicing in figured and plain grades. While it is not as hard as some other veneer woods, it sands to a distinctive silky polished finish.

Magnolia is one of the diffuse-porous woods and its grain is usually straight but more conspicuous than Poplar. Its annual growth rings are generally distinct with a thin whitish line at the beginning and end of each year's growth. The wood is of compact structure and its hardness is medium hard, similar to that of Black Walnut or Tupelo. Magnolia's strength properties are somewhat over average and it ranks close to the top as a bending wood. It is moderately low in shrinkage, moderately stiff and moderately weak in compression. Although it does not possess good decay resistance, Magnolia ranks high in shock resistance and has better than average stability. Magnolia machines very well in all operations with the exception of shaping and mortising. It can often be planed to a degree of smoothness that requires little or no sanding and works easily and with good sharp detail at the moulder and turning lathes. Its general favorable working properties serve to bring Magnolia to the attention of woodworking plants during the early days of lumber shortages. From a wood that was totally unknown to many industries, Magnolia is now used in large quantities by the industry and has become a favorite wood for certain special uses.

Magnolia lends itself readily to practically any type of commercial finish. Where it was formerly finished chiefly in paint or enamel finishes, Magnolia is now much used in the popular natural and bleached blonde finishes. It sands and polishes to a satiny luster and since it does not require filling for any type of finish, it is a most economical wood to finish. Although Magnolia's figure is usually mild, selected lumber is available to enable the production of striking natural finish effects.

It has been estimated that about two-thirds of all the Magnolia lumber used in manufacturing wood products now goes into furniture. While furniture manufacturers were very slow to appreciate the superior steam bending qualities of Magnolia, its use for bentwood products, chair and frame parts is increasing annually. Furniture plants have also found Magnolia well suited for furniture frames and are currently using it in solid furniture to be finished in the popular blonde and pickled finishes. Magnolia has always been quite popular for painted and enameled breakfast and kitchen furniture. It is also reported to make a very good imitation satinwood.

Probably one of the most exacting, extensive and popular uses for Magnolia is found in the manufacture of venetian blinds. Venetian blind manufacturers found Magnolia to be admirably suited for their use, particularly for blind slats, and take full advantage of its fine, uniform texture, sufficient hardness, and inherent property of remaining flat without warping.

Next to furniture use, the most popular usage of Magnolia is found in the manufacture of planing-mill and mill-work products. It is said that about 50% of all the Cucumber Magnolia cut goes into millwork as well as the large quantity of Evergreen Magnolia. Magnolia's workability and paintholding properties have made it extremely popular for interior finish, siding, interior trim, moulding, doors and paneling. It is even used for car sheathing. Store fixture concerns make good use of Magnolia, using it all the way from store fronts to cabinets and counters.

The superior nailholding properties of Magnolia, as well as its natural resistance to splitting, has made it a favored wood for boxes and crates. The fact that it has no tendency to impart either taste or odor has also led to its use for egg cases, cheese boxes, pails, tubs and woodenware used in the shipment, storage and serving of food products. Other common uses for Magnolia include: agricultural implements, boats, broom and brush handles, cotton gins, excelsior, casket trim, kitchen and utility cabinets, mine timbers, sleds, toy wagons, hay racks and wagon boxes. Many other uses are being developed daily as the woodworking industry becomes aware of the versatility and favorable properties of Magnolia as applied to its products.

Natives of the Allegheny region like to tell that the early settlers of that region used to collect the cone-like fruits of the Magnolia tree and steeped them in whiskey to make a medicine to ward off an autumnal fever which was common to that section. Some even continue to make this bitter medicine which is quite difficult to take in spite of the whiskey contained.

|

Botanical Name |

Magnolia grandiflora |

| Origin | Southeastern United States |

| Janka Hardness | 1020 lbf |

| Average Dried Weight | 35 lbs/ft3 |

| Workability | Easy to work with both machine and hand tools. Turns, glues, stains and finishes well. |

| Related Species |

Cucumbertree (Magnolia acuminata) Sweetbay (Magnolia virginiana) |

Magnolia

4/4

4050 Old Cornelia Hwy

Gainesville GA 30507

United States

Wood Calculator Section

Need Help Figuring out how much you need ?

One Board foot = 144 Cubic Inches

Example: If you need a piece of wood 12 inches wide, 1 inch thick and 24 inches long, that is equal to 2 board feet.

12 inches x 1 inch x 24 inches = 288 inches. 288/ 144 = 2 board feet